| Beverage Machines |

Food Machines |

Used Machines | Advice | Info | |||||

FRUIT PULPER AND DESTONER - D100 |

|||

|

Designed and built to meet the needs of small manufacturers, as the cost of the only small machine on the market so far is too high to justify the investment. We have not only reduced costs but also improved operation, adopting solutions that until now were only applied to machines with higher productivity Machine for the production of fruit purees, tomato puree and juice extraction. The machine separates the waste parts (peel, stones, seeds of berries or tomato etc.) obtaining a basic puree for the next concentration in jams or sauce. |

| CHARACTERISTICS : | ||||||||||||

Details |

|

Depending on the diameter of the basket holes, you can choose how and what to sieve. A few examples :

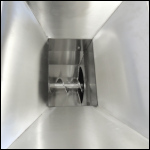

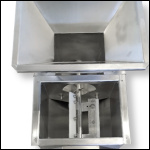

The loading hopper has a feed screw through which the products are directed towards the sieving chamber. This allows a constant quantity of product to be processed in the sieving chamber, avoiding overloading theshovels that smear the product on the inner wall of the sieve basket and would not have time to process the product, making it advance to the expulsion mouth. Made of AISI 304 stainless steel and composed of:

TECHNICAL DATA:

|

||||||||||

|

|

||||||||||||

| Request info on this product >> | ||